Why Auzac

Discover the difference in the Auzac approach to manufacturing all of our offerings, including our original Samurai lifting products.

Quality Management

Since our founding, we have continued to manufacture indispensable wire

sockets, hook blocks as well as

other types of hoisting attachment products for large-scale buildings.

They are mounted on bridges, construction equipment, cranes and so forth, and are used day and night

under

tough conditions.

Looking into the future, we are aiming to achieve even better quality so that our customers can use our

products with confidence.

As a result, we are constantly implementing the strictest quality management practices, and we are

aiming to

be a company that has "suppleness", which can respond to any requirement flexibly.

We strive to connect not only articles to articles but also hearts and hearts, and dreams and dreams.

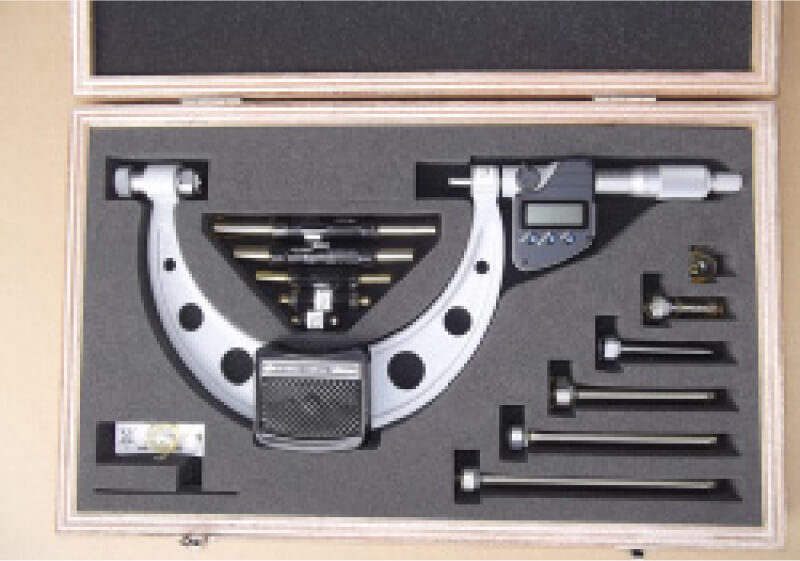

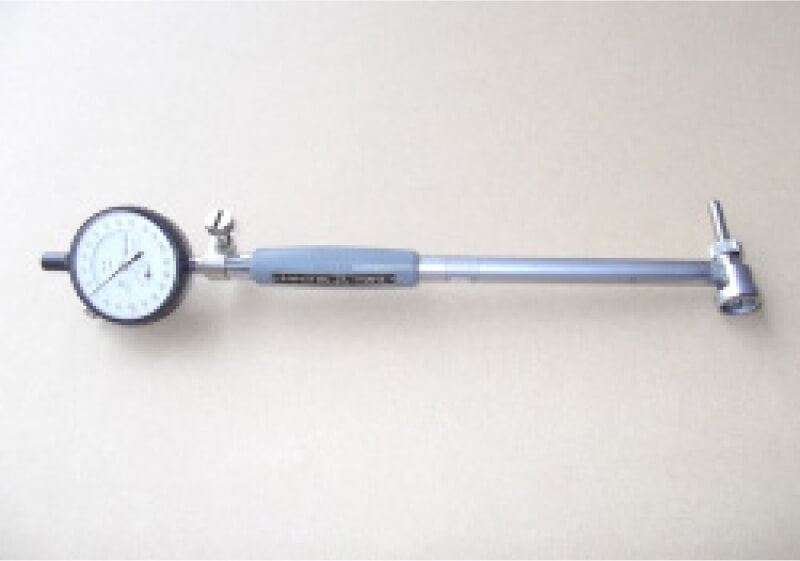

Inspection System

Inspection Equipment

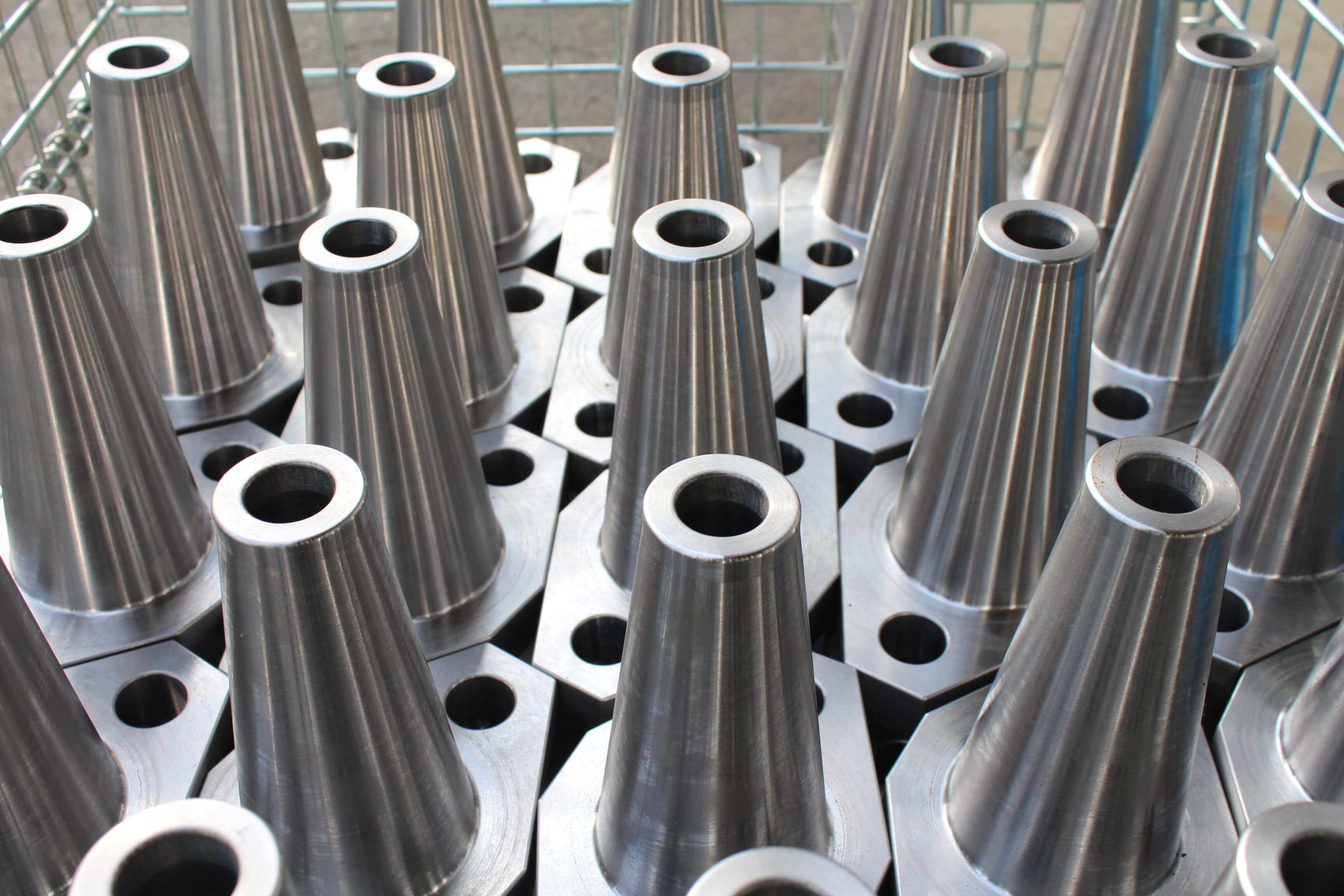

Processing Technique

We manufacture products with a spirit of craftsmanship to meet the demands of our various customers.

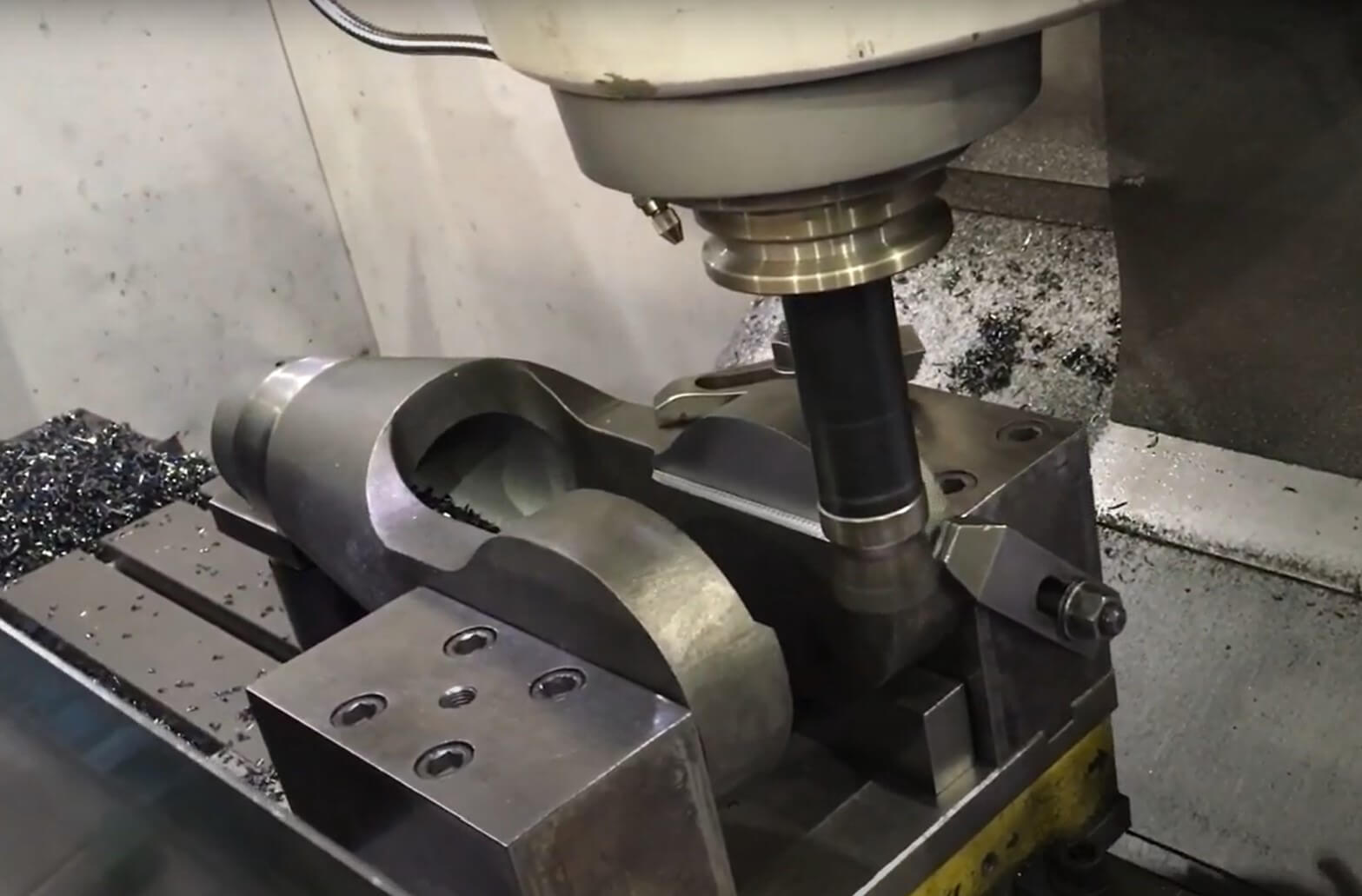

To produce high quality products, you need to use advanced manufacturing technology. At Auzac, we bring a half century of expertise in spelter socket manufacturing to our processing with the latest machine tools to produce high precision products. The design process is also essential to both form and guarantee the strength of the product. In Japan, we also manufacture custom-made spelter sockets, and provide the design technology to meet a wealth of customer requirements.

Metal Processing

We mainly manufacture terminal hardware of wire ropes.

Recently, we also

perform the processing of complex shapes and three-dimensional shapes using 3D CAD/CAM and a CNC lathe

with

milling cutter.Our factory is equipped with the facilities that can meet various requirements from heavy

cutting to precision processing and from circular objects to platy objects.We have been making every

effort

to attain the highest levels of customer satisfaction.

A mindset focused on improvement

By keeping our factory lean and clean, we can work more efficiently.

At Auzac, we continue our efforts to improve productivity by adopting the "Kaizen" (literally,

"improvement") mindset, a concept advocated by Toyota Motor Corporation. We also engage in the 5S

activities, which include seiri (organization), seiton (orderliness), seiso (cleaning), seiketsu (hygeine),

and shitsuke (discipline).

We are working to cut out anything unnecessary in order to improve our working speed, working efficiency and

workplace communication.

Of course, this does not mean disregarding our employees.

We have installed high-performance machines and the factory's internal layout is simple. In addition, we pay

constant attention to cleanliness and safety.

Our factory has been created with a primary focus on promptly meeting customer requirements while minimizing

costs.